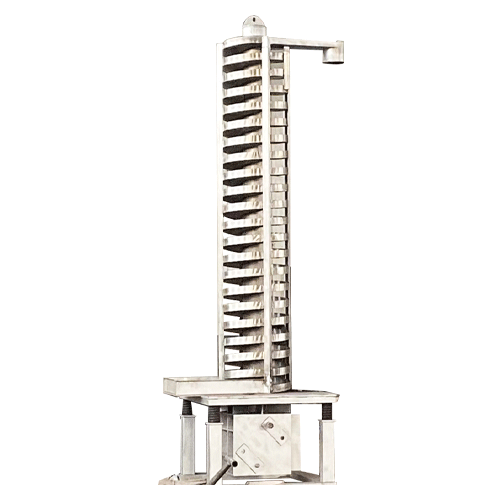

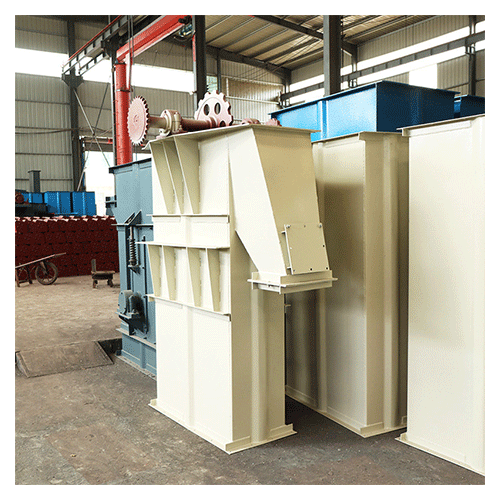

Ne系列板链斗式提升机

NE SERIES CHAIN-PL ATE BUCKET ELEVATOR

一、概述Summary

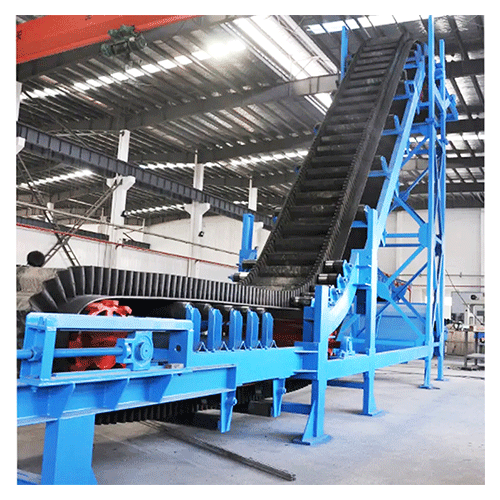

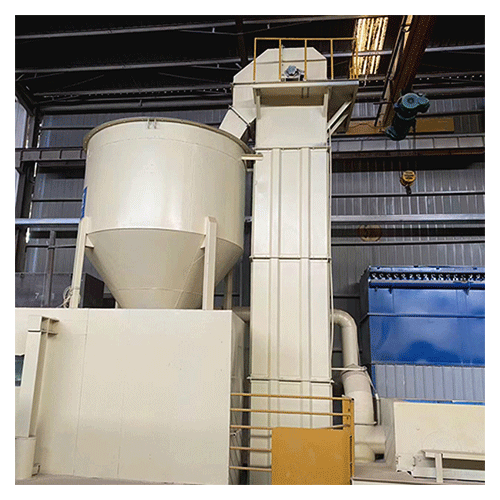

NE系列板链式提升机是引进国内外先进技术开发的产品。该系列提升机适用于垂直输送粉状、粒装和块状物料,也可提升磨琢性大的物料,物料温度一般不超过200C,提升高度最高40m。

NE series chain-plate bucket elevator has been researched and developed by introducing advanced technologies athome and abroad. The NE series elevators apply to transporting materials such as powder, pellet, particulate even with moresurface friction. The temperature of materials is up to 200'C, and the lifting height can reach up to 40m.

二、技术参数Technical Par ameters

NE系列提升机的技术参数见表3-1

表3-1NE系列提升机技术参数

Table 3-1 NE Series Hoist Technical Parameters

| 型号 Model |

提升量m³/h Capacity |

物料最大块度(mm) Max Paricle |

||||

| 允许占百分比% | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | 16 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 31 | 90 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 165 | 130 | 105 | 80 | 65 | 70 |

| NE200 | 220 | 170 | 135 | 100 | 85 | 70 |

| NE300 | 320 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 441 | 205 | 165 | 125 | 105 | 90 |

| NE500 | 470 | 240 | 190 | 145 | 120 | 100 |

| NE600 | 600 | 240 | 190 | 145 | 120 | 100 |

| NE800 | 800 | 275 | 220 | 165 | 135 | 110 |

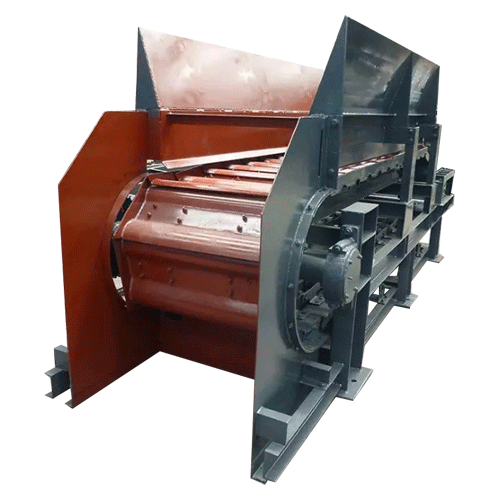

三、提升机的结构Elevator Structure

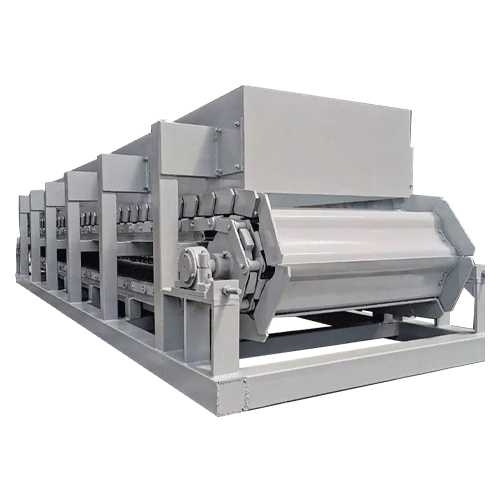

NE系列板链式提升机由运行部件、驱动装置、上部装置、中部机壳、下部装置组成。

运行部件—由料斗和专用板式链条组成,NE30 及以下采用单排链,NE50—NE800采用双排链。

驱动装置—采用多种驱动组合驱动,(依用户实际需要而定)。驱动平台上装有检修架和栏杆。驱动装置分左装和右装两种。

上部装置—安装有轨道(双排链)、逆止器、卸料口装有防回料橡胶板。

中间节—部分中间节装有轨道(双链),以防止链条工作中摆动。

下部装置—安装有自动张紧装置。

四、提升机的动力配备 Elevator Power Equipment

NE15、NE30、NE50、NE100、NE150、NE200、NE300、NE400 型提升机的最大提升量、最大提升高度及动力配备见表3-2。

表3-2NE系列板链式提升机动力配备表

Table 3-2 NE Series Chain-Plate Bucket Elevator Matching Power Chart

| 型号 Model |

输送量m³/h Capacity |

驱动装置 Drive Unit |

相应动力可提升最大高度(m) Max.Height |

适宜物料 Suitable |

||||||||

| 功率kw Power | 减速机 减速比 Reduce Ratio |

物料容量(t/m³) Density |

||||||||||

| 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | |||||

| NE15 | 10 | 1.5 | 47 | 30.28 | 28.78 | 27.78 | 25.78 | 21.78 | 17.28 | 15.28 | 23.28 | 粉状Powdery 小颗粒状 Small Granularity |

| 2.2 | 47 | 24.28 | 23.28 | 22.28 | 21.28 | |||||||

| 1.5 | 29 | 30.78 | 24.28 | 17.28 | 14.28 | 11.78 | 8.28 | 7.28 | 6.28 | 粉状Powdery 小颗粒状 Small Granularity |

||

| 16 | 2.2 | 29 | 28.78 | 27.28 | 23.28 | 18.28 | 15.78 | 13.78 | 12.28 | |||

| 3.0 | 29 | 25.78 | 24.28 | 23.28 | 19.28 | 17.28 | ||||||

| 4.0 | 29 | 22.28 | 21.28 | |||||||||

| NE30 | 18.5 | 1.5 | 47 | 28.13 | 18.63 | 14.63 | 11.63 | 8.13 | 7.13 | 6.13 | 5.13 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

| 2.2 | 47 | 42.13 | 31.13 | 24.13 | 18.13 | 15.63 | 13.13 | 9.63 | 8.63 | |||

| 3.0 | 47 | 47.63 | 43.13 | 34.13 | 28.13 | 26.63 | 18.63 | 16.63 | 14.636 | |||

| 4 | 47 | 44.13 | 41.47 | 38.13 | 32.13 | 28.13 | 24.63 | 22.13 | ||||

| 5.5 | 47 | 38.63 | 36.13 | 34.13 | 32.13 | 30.63 | ||||||

| 31 | 1.5 | 29 | 14.63 | 8.63 | 6.63 | 5.13 | 4.13 | 粉状Powdery 小颗粒状 Small Granularity |

||||

| 2.2 | 29 | 24.13 | 16.13 | 12.63 | 8.63 | 7.13 | 5.63 | 5.13 | 4.13 | |||

| 3 | 29 | 33.63 | 24.63 | 17.63 | 14.63 | 12.13 | 8.63 | 7.63 | 6.63 | |||

| 4 | 29 | 45.63 | 33.63 | 28.63 | 21.63 | 17.13 | 14.63 | 12.63 | 9.63 | |||

| 5.5 | 29 | 47.13 | 43.63 | 37.63 | 30.63 | 26.13 | 22.63 | 18.13 | 16.13 | |||

| 7.5 | 29 | 40.63 | 38.13 | 35.63 | 31.63 | 22.63 | 24.63 | |||||

| 11 | 29 | 33.63 | 61.63 | 29.63 | ||||||||

| NE50 | 35 | 1.5 | 47 | 12.63 | 7.63 | 5.65 | 4.63 | 3.63 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

|||

| 2.2 | 47 | 19.63 | 14.13 | 9.13 | 7.63 | 6.13 | 5.13 | 4.13 | 3.63 | |||

| 3 | 47 | 29.63 | 21.63 | 15.63 | 12.63 | 9.13 | 7.63 | 6.63 | 5.63 | |||

| 4 | 47 | 40.63 | 29.63 | 23.63 | 17.63 | 14.63 | 12.63 | 9.63 | 8.13 | |||

| 5.5 | 47 | 49.13 | 41.63 | 33.13 | 27.13 | 23.13 | 27.63 | 24.63 | 21.63 | |||

| 7.5 | 47 | 45.63 | 41.63 | 37.63 | 32.12 | 27.63 | 24.63 | 21.63 | ||||

| 11 | 47 | 38.63 | 36.63 | 34.13 | 32.13 | 30.13 | ||||||

| 60 | 1.5 | 29 | 5.63 | 3.63 | 粉状Powdery 小颗粒状 Small Granularity |

|||||||

| 2.2 | 29 | 9.13 | 6.15 | 4.63 | 3.63 | |||||||

| 3 | 29 | 15.13 | 9.13 | 7.13 | 5.63 | 4.63 | 3.63 | 3.13 | ||||

| 4 | 29 | 22.63 | 15.13 | 10.13 | 8.13 | 6.63 | 5.63 | 4.63 | 4.13 | |||

| 5.5 | 29 | 32.13 | 23.63 | 17.13 | 13.63 | 9.63 | 8.13 | 7.13 | 6.13 | |||

| 7.5 | 29 | 44.63 | 32.63 | 25.63 | 19.63 | 16.63 | 14.13 | 12.13 | 9.13 | |||

| 11 | 29 | 48.63 | 44.63 | 38.63 | 32.13 | 27.13 | 23.63 | 19.13 | 16.63 | |||

| 15 | 29 | 41.13 | 38.13 | 36.65 | 33.13 | 28.63 | 25.63 | |||||

| 18.5 | 23 | 31.13 | 29.13 | |||||||||

续表3-2NE 系列板链式提升机动力配备表

Table 3-2 NE Series Chain-Plate Bucket Elevator Matching Power Chart

| 型号 Model |

输送量m³/h Capacity |

驱动装置 Drive Unit |

相应动力可提升最大高度(m) Max.Height |

适宜物料 Suitable |

||||||||

| 功率kw Power | 减速机 减速比 Reduce Ratio |

物料容量(t/m³) Density |

||||||||||

| 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | |||||

| NE100 | 75 | 5.5 | 47 | 25.15 | 16.65 | 13.15 | 8.65 | 7.65 | 6.15 | 5.15 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

|

| 7.5 | 47 | 35.15 | 25.65 | 19.65 | 15.15 | 12.65 | 9.15 | 7.65 | 6.65 | |||

| 11 | 47 | 49.15 | 38.65 | 30.65 | 25.15 | 19.65 | 16.65 | 14.65 | 13.15 | |||

| 15 | 47 | 44.65 | 41.15 | 35.15 | 29.65 | 25.65 | 22.65 | 18.65 | ||||

| 18.5 | 29 | 37.65 | 35.15 | 32.15 | 28.65 | 25.65 | ||||||

| 22 | 29 | 32.65 | 30.65 | 28.65 | ||||||||

| 110 | 5.5 | 29 | 15.15 | 9.15 | 6.65 | 5.65 | 粉状Powdery 小颗粒状 Small Granularity |

|||||

| 7.5 | 29 | 23.15 | 15.65 | 12.15 | 8.15 | 6.65 | 5.65 | |||||

| 11 | 29 | 33.15 | 25.65 | 18.65 | 15.15 | 12.65 | 9.15 | 7.65 | 6.65 | |||

| 15 | 29 | 48.65 | 35.65 | 25.15 | 23.15 | 18.15 | 15.65 | 13.65 | 12.15 | |||

| 18.5 | 23 | 44.15 | 35.65 | 29.15 | 24.65 | 19.65 | 17.15 | 15.15 | ||||

| 22 | 23 | 40.65 | 35.15 | 29.65 | 25.65 | 22.65 | 18.65 | |||||

| 30 | 23 | 37.15 | 34.65 | 32.15 | 30.15 | 28.15 | ||||||

| NE150 | 112 | 5.5 | 47 | 14.6 | 9.1 | 6.6 | 5.1 | 4.1 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

|||

| 7.5 | 47 | 22.6 | 15.1 | 11.6 | 8.1 | 6.6 | 5.6 | 4.6 | ||||

| 11 | 47 | 34.6 | 25.1 | 18.1 | 14.6 | 12.6 | 9.1 | 7.6 | 6.6 | |||

| 15 | 47 | 47.6 | 35.1 | 27.6 | 22.6 | 17.6 | 15.1 | 13.1 | 11.6 | |||

| 18.5 | 29 | 52.6 | 43.6 | 34.3 | 28.6 | 24.1 | 19.1 | 16.6 | 15.1 | |||

| 22 | 29 | 47.6 | 41.6 | 34.6 | 29.1 | 25.1 | 22.1 | 18.1 | ||||

| 30 | 29 | 43.1 | 39.6 | 36.1 | 33.6 | 31.1 | 27.6 | |||||

| 37 | 29 | 31.6 | 29.1 | |||||||||

| 170 | 7.5 | 29 | 13.6 | 8.1 | 6.1 | 4.6 | 粉状Powdery 小颗粒状 Small Granularity |

|||||

| 11 | 29 | 22.6 | 15.1 | 9.6 | 7.6 | 6.5 | 5.6 | 4.6 | ||||

| 15 | 29 | 31.6 | 23.1 | 16.6 | 13.6 | 9.6 | 8.1 | 7.1 | 6.1 | |||

| 18.5 | 23 | 39.6 | 29.1 | 22.6 | 17.1 | 14.6 | 12.6 | 9.1 | 8.1 | |||

| 22 | 23 | 47.6 | 35.1 | 27.6 | 22.6 | 17.6 | 15.1 | 13.1 | 9.6 | |||

| 30 | 23 | 51.6 | 46.6 | 38.6 | 31.6 | 26.6 | 23.1 | 18.6 | 16.6 | |||

| 37 | 23 | 42.1 | 38.6 | 33.6 | 29.1 | 25.6 | 22.6 | |||||

| 45 | 23 | 35.6 | 33.1 | 30.6 | 28.6 | |||||||

续表3-2NE 系列板链式提升机动力配备表

Table 3-2 NE Series Chain-Plate Bucket Elevator Matching Power Chart

| 型号 Model |

输送量m³/h Capacity |

驱动装置 Drive Unit |

相应动力可提升最大高度(m) Max.Height |

适宜物料 Suitable |

||||||||

| 功率kw Power | 减速机 减速比 Reduce Ratio |

物料容量(t/m³) Density |

||||||||||

| 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | |||||

| NE200 | 176 | 15 | 43 | 28.23 | 20.73 | 13.23 | 10.23 | 8.23 | 6.73 | 6.23 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

|

| 18.5 | 29 | 39.23 | 25.73 | 19.73 | 13.23 | 11.23 | 9.73 | 8.23 | ||||

| 22 | 29 | 47.23 | 34.73 | 24.23 | 29.73 | 14.23 | 11.73 | 10.23 | 9.23 | |||

| 30 | 29 | 47.23 | 37.23 | 28.23 | 23.73 | 20.73 | 17.73 | 13.23 | ||||

| 37 | 29 | 47.23 | 39.23 | 33.23 | 25.73 | 23.23 | 20.23 | |||||

| 45 | 29 | 46.23 | 40.73 | 35.23 | 28.23 | 25.25 | ||||||

| 220 | 18.5 | 23 | 27.23 | 19.23 | 12.23 | 9.73 | 8.23 | 6.73 | 5.23 | 粉状Powdery 小颗粒状 Small Granularity |

||

| 22 | 23 | 35.73 | 23.23 | 18.23 | 12.23 | 10.23 | 8.23 | 723 | 5.73 | |||

| 30 | 23 | 49.73 | 3673 | 26.23 | 21.23 | 17.23 | 12.23 | 11.23 | 9.73 | |||

| 37 | 23 | 46.23 | 35.73 | 27.23 | 22.73 | 19.23 | 13.73 | 12.23 | ||||

| 45 | 23 | 44.23 | 36.23 | 28.23 | 24.23 | 21.23 | 19.23 | |||||

| 55 | 23 | 45.23 | 38.23 | 32.73 | 26.23 | 23.23 | ||||||

| 75 | 23 | 52.23 | 46.23 | 40.73 | 36.73 | |||||||

| NE300 | 250 | 15 | 43 | 19.23 | 14.23 | 9.23 | 7.23 | 5.73 | 4.73 | 4.23 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

|

| 18.5 | 29 | 26.73 | 17.73 | 13.73 | 9.23 | 7.73 | 6.73 | 5.73 | 4.73 | |||

| 22 | 29 | 32.23 | 23.73 | 16.73 | 13.73 | 9.73 | 8.23 | 7.23 | 6.23 | |||

| 30 | 29 | 44.23 | 32.73 | 25.73 | 19.23 | 16.23 | 14.23 | 12.23 | 9.23 | |||

| 37 | 29 | 54.73 | 38.73 | 32.23 | 26.73 | 22.73 | 17.73 | 15.73 | 13.73 | |||

| 45 | 29 | 48.73 | 39.73 | 31.73 | 2773 | 19.23 | 26.23 | 17.23 | ||||

| 55 | 29 | 43.73 | 39.73 | 34.23 | 29.73 | 26.23 | 23.73 | |||||

| 75 | 29 | 36.73 | 33.73 | 32.73 | 29.23 | |||||||

| 320 | 18.5 | 23 | 18.73 | 13.23 | 8.73 | 6.73 | 5.73 | 4.73 | 3.73 | 粉状Powdery 小颗粒状 Small Granularity |

||

| 22 | 23 | 24.73 | 16.73 | 12.73 | 8.73 | 7.23 | 5.73 | 5.73 | 4.23 | |||

| 30 | 23 | 34.23 | 25.23 | 18.23 | 14.73 | 12.23 | 8.73 | 7.73 | 6.73 | |||

| 37 | 23 | 42.73 | 31.73 | 24.73 | 18.73 | 15.73 | 13.23 | 9.73 | 8.73 | |||

| 45 | 23 | 44.73 | 38.73 | 30.73 | 25.23 | 19.73 | 16.73 | 14.23 | 13.23 | |||

| 55 | 23 | 54.23 | 47.73 | 35.23 | 31.23 | 26.23 | 22.73 | 18.23 | 16.23 | |||

| 75 | 23 | 48.23 | 43.73 | 30.73 | 36.23 | 31.73 | 28.23 | 25.23 | ||||

| NE400 | 310 | 15 | 43 | 15.1 | 10.8 | 粉状Powdery 小颗粒状 Small Granularity 块状Bulk |

||||||

| 22 | 43 | 26.8 | 19.3 | 15.3 | 12.4 | 10.3 | ||||||

| 30 | 43 | 32.2 | 23.7 | 18.6 | 15.1 | 12.7 | 10.8 | |||||

| 37 | 43 | 44.8 | 33.1 | 16.1 | 21.4 | 18 | 15.5 | 13.6 | 12 | |||

| 45 | 43 | 54.7 | 41.3 | 32.6 | 26.8 | 22.7 | 19.3 | 17.2 | 15.3 | |||

| 75 | 43 | 48.7 | 43.9 | 39.9 | 34.8 | 30.2 | 26.6 | 23.7 | ||||

| 90 | 43 | 36.6 | 33.7 | 31.3 | 29.1 | |||||||

| 420 | 18.5 | 43 | 14.3 | 10.2 | 粉状Powdery 小颗粒状 Small Granularity |

|||||||

| 22 | 29 | 18.1 | 13.1 | 10 | ||||||||

| 30 | 29 | 21.9 | 15.9 | 12.3 | 9.9 | |||||||

| 37 | 29 | 30.6 | 22.4 | 17.5 | 14.3 | 11.9 | ||||||

| 45 | 29 | 38.2 | 28.2 | 22.1 | 18.1 | 15.2 | 13.1 | 11.4 | ||||

| 55 | 29 | 46.9 | 34.7 | 27.3 | 22.4 | 18.9 | 16.3 | 14.3 | 12.6 | |||

| 75 | 29 | 54.7 | 42.8 | 33.9 | 27.9 | 23.6 | 20.4 | 17.9 | 15.6 | |||

| 90 | 29 | 48.7 | 43.9 | 38.8 | 32.9 | 28.6 | 25.2 | 22.4 | ||||

注:功率参数是料斗100%充满时的所用功率,设计时请根据实际提升及提升高度适当变动。

五、提升机的外形尺寸Profile Dimensions Of Elevator

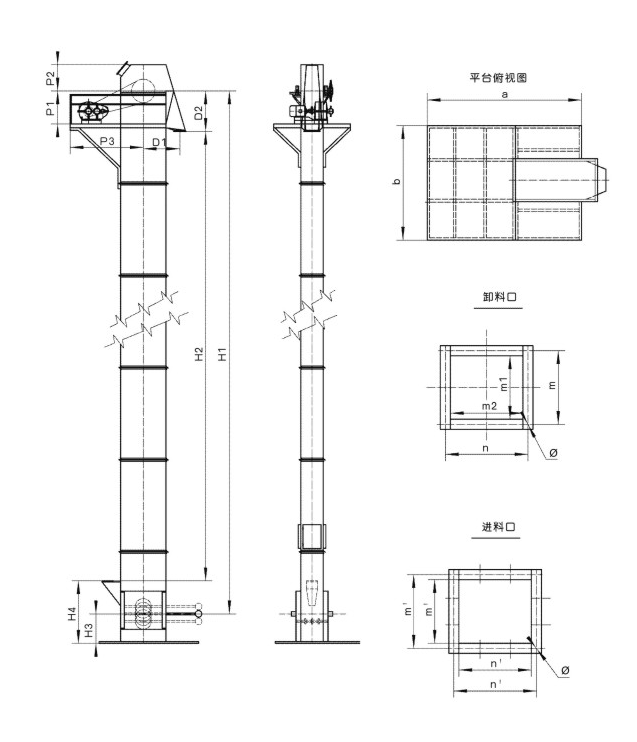

NE系列板链式提升机的外形如图3-1和图3-2所示,其尺小见表3-3

表3-3NE系列板链式提升机外形尺寸表

Table 3-3 NE Series Chain-Plate Bucket Elevator Profile Dimensions Chart

| 提升机型号(Model) | NE15 | NE30 | NE50 | NE100 | NE150 | NE200 | NE300 | NE400 | NE500 | NE600 | NE800 | |

| 机壳型式(Body Model) | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅱ | Ⅱ | Ⅱ | Ⅲ | Ⅲ | Ⅲ | |

| 上机壳 Upper Body |

H1 | 523 | 713 | 720 | 766 | 766 | 968 | 968 | 1168 | 1300 | 1300 | 1450 |

| H2 | 1342 | 1343 | 1390 | 1670 | 1700 | 178 | 1780 | 2030 | 3000 | 3000 | 3000 | |

| 卸料口 Outlet |

D1 | 900 | 1100 | 1100 | 1300 | 1100 | 1650 | 1650 | 1900 | 2200 | 2200 | 2500 |

| D2 | 800 | 1000 | 1000 | 1200 | 1200 | 1500 | 1500 | 1750 | 1950 | 1950 | 2000 | |

| D3 | 250 | 300 | 350 | 350 | 700 | 550 | 550 | 600 | 700 | 700 | 850 | |

| D4 | 300 | 350 | 400 | 500 | 650 | 650 | 950 | 1000 | 1050 | 1300 | 1500 | |

| d1 | 306/3 | 356/3 | 406/3 | 406/3 | 456/3 | 606/4 | 606/4 | 670/4 | 756/5 | 456/5 | 906/6 | |

| d2 | 356/3 | 406/3 | 456/3 | 556/3 | 706/5 | 706/5 | 1006/7 | 1070/7 | 1106/7 | 1356/9 | 1556/10 | |

| 平台 Platform | p1 | 1000 | 1000 | 850 | 1200 | 1200 | 1280 | 1280 | 1530 | 1500 | 1500 | 1500 |

| p2 | 104 | 104 | 103 | 130 | 130 | 144 | 144 | 144 | 160 | 160 | 180 | |

| p3 | 1404 | 1604 | 1753 | 1740 | 1740 | 1864 | 1864 | 2414 | 3200 | 3200 | 3600 | |

| p4 | 512 | 616 | 616 | 720 | 720 | 870 | 870 | 1080 | 1310 | 1310 | 1500 | |

| p5 | 1579 | 1984 | 1694 | 2380 | 2380 | 2730 | 2730 | 2930 | 3200 | 3200 | 3600 | |

| p6 | 2300 | 2500 | 2500 | 3000 | 3300 | 3800 | 4100 | 4100 | 4500 | 4800 | 5300 | |

| 中间机关 Middle Body |

M1 | 1050 | 1240 | 1240 | 1450 | 1450 | 1750 | 1750 | 2150 | 2450 | 2450 | 2800 |

| M2 | 1156 | 1346 | 1348 | 1528 | 1528 | 1888 | 1888 | 2290 | 2600 | 2600 | 2950 | |

| M3 | 450 | 500 | 650 | 800 | 1060 | 1120 | 1420 | 1445 | 1535 | 1800 | 2050 | |

| M4 | 556 | 606 | 780 | 932 | 1196 | 1280 | 1580 | 1585 | 1685 | 1950 | 2200 | |

| M5 | 1250 | 1440 | 1440 | 1680 | 1680 | 1980 | 1980 | 2400 | 2710 | 2710 | 3060 | |

| M6 | 650 | 700 | 850 | 1030 | 1290 | 1350 | 1650 | 1700 | 1700 | 2060 | 2310 | |

| 喂料口 Inlet |

R1 | 800 | 970 | 970 | 1125 | 1075 | 1300 | 1300 | 1550 | 1775 | 1775 | 2000 |

| R2 | 250 | 300 | 280 | 400 | 500 | 550 | 550 | 650 | 700 | 700 | 800 | |

| R3 | 250 | 300 | 300 | 400 | 600 | 560 | 860 | 850 | 950 | 1200 | 1400 | |

| R4 | 1350 | 1650 | 1700 | 2000 | 2050 | 2400 | 2400 | 2900 | 3300 | 3350 | 3750 | |

| r2 | 306/3 | 356/3 | 336/3 | 456/3 | 556/3 | 620/4 | 620/4 | 720/5 | 770/5 | 770/5 | 670/6 | |

| r3 | 306/3 | 356/3 | 356/3 | 456/3 | 656/3 | 630/4 | 930/6 | 920/6 | 1020/7 | 1027/8 | 1410/10 | |

| 下机壳 Bottom Body |

B1 | 600 | 750 | 750 | 850 | 900 | 1050 | 1050 | 1400 | 1550 | 1600 | 1800 |

| B2 | 2440 | 2440 | 2500 | 2500 | 2500 | 3000 | 3000 | 3000 | 3500 | 3500 | 4000 | |

| B3 | 830 | 970 | 1102 | 1372 | 1632 | 2102 | 2102 | 2131 | 2160 | 2440 | 2700 | |

| 地基及基础尺寸 Foundation Dm. |

Z1 | 1000 | 1200 | 1200 | 1400 | 1400 | 1670 | 1670 | 1970 | 2220 | 2220 | 2500 |

| Z2 | 1400 | 1500 | 1500 | 1700 | 1700 | 1850 | 1850 | 2150 | 2300 | 2300 | 2500 | |

| Z3 | 950 | 1000 | 1100 | 1200 | 1350 | 1350 | 1550 | 1600 | 1650 | 1800 | 2000 | |

| Z4 | 1300 | 1400 | 1700 | 1900 | 2350 | 2350 | 2900 | 2950 | 3100 | 3500 | 4100 | |

| Z5 | 554 | 594 | 744 | 916 | 1176 | 1250 | 1550 | 1565 | 1662 | 1926 | 2175 | |

| Z6 | 400/1 | 450/1 | 550/1 | 600/1 | 400/1 | 800/1 | 750/1 | 720/1 | 1662/3 | 1962/3 | 2175/3 | |

| Z7 | 1144 | 1334 | 1334 | 1566 | 1566 | 1566 | 1880 | 2270 | 2576 | 2576 | 2920 | |

| Z8 | 500/1 | 600/1 | 600/1 | 700/1 | 700/1 | 940/2 | 940/2 | 720/1 | 2576/4 | 2576/4 | 2920/4 | |

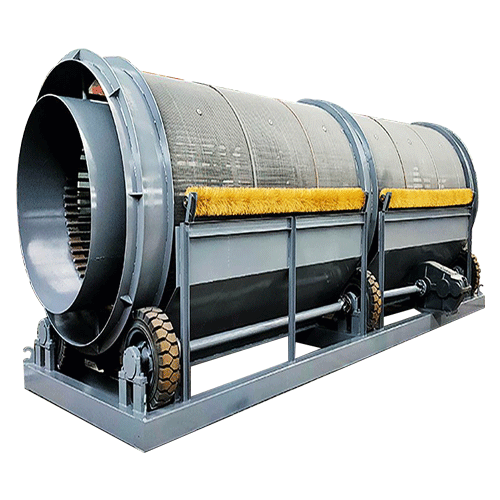

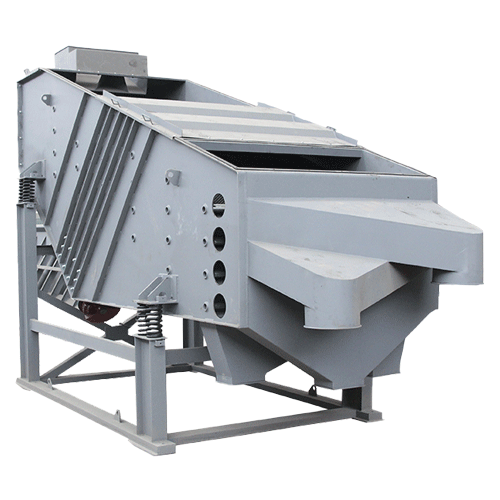

图3-1NE系列提升机结构外形图

Figure 3-1 NE Series Elevator Outside View

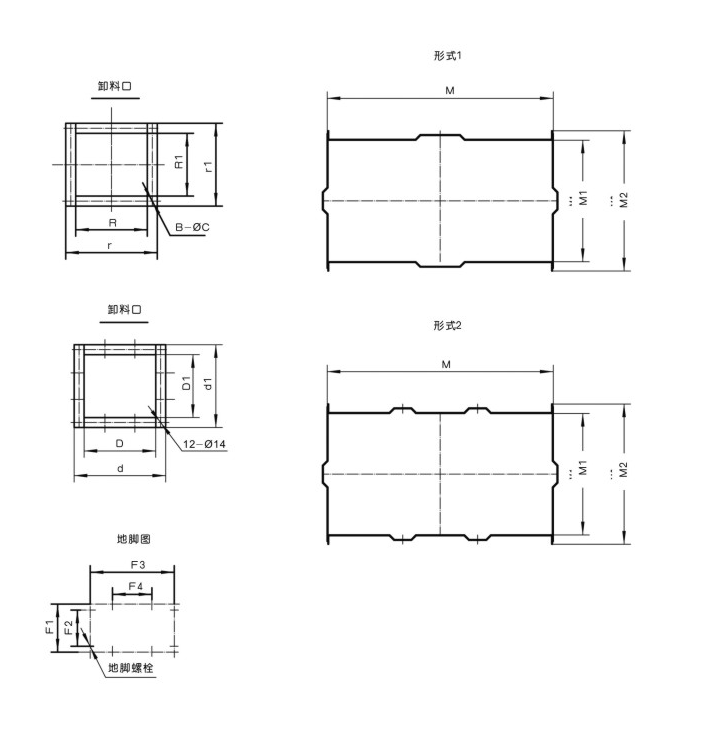

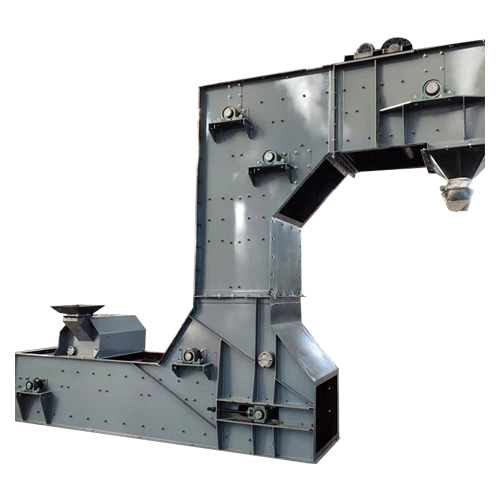

图3-2NE系列提升机机壳型式及地脚图

Figure 3-1 NE Series Winding Machine Body Type And Foundation Drawing

斗式提升机.png)